ADVANCED FUELS CRUCIAL TO ENERGY MIX

Advanced biofuels play an important role in cutting carbon emissions in transport, including road, rail, shipping and aviation. Transport comprises 27% of emissions in Europe and 23% of global carbon emissions. Different solutions are needed to move towards carbon neutrality by 2050, if not before.

Learn about the value chain of advanced renewable fuels, where and how they work, and why they are important to the overall energy mix.

What are advanced renewable fuels?

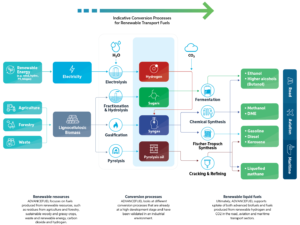

In the context of the ADVANCEFUEL project, renewable fuels (RESfuels) refer to liquid advanced biofuels produced from lignocellulosic feedstock (agriculture and forest residues and waste) and liquid renewable alternative fuels produced from renewable hydrogen and CO2 streams.

What are advanced renewable fuels?

In the context of the ADVANCEFUEL project, renewable fuels (RESfuels) refer to liquid advanced biofuels produced from lignocellulosic feedstock (agriculture and forest residues and waste) and liquid renewable alternative fuels produced from renewable hydrogen and CO2 streams.

RETHINKING BIOFUELS

Their sustainability has been questioned – especially in the case of biofuels.

What do many think about biofuels? What are the facts about advanced biofuels?

Hover over the boxes below and learn about the new generation of biofuels – known as advanced biofuels.

Biofuels produce carbon emissions along the supply chain.

Advanced biofuels demonstrate high greenhouse gas emission savings.

Biofuels are not sustainable.

Sustainability criteria play an essential role for the market uptake by offering trust and transparency.

Biofuels increase pressure on land use change.

Advanced biofuels indicate a low risk of causing Indirect Land Use Change.

Biofuels are produced from food or trees.

Advanced biofuels by definition are sourced from forest biomass, residues, waste, non-food-crops and do not compete with food or agricultural land-use.

There are better sustainable mobility options than renewable fuels.

Advanced biofuels are amongst the most promising options to reduce carbon emission for aviation and shipping.

RETHINKING BIOFUELS

Their sustainability has been questioned – especially in the case of biofuels.

What do many think about biofuels? What are the facts about advanced biofuels?

Hover over the boxes below and learn about the new generation of biofuels – known as advanced biofuels.

Biofuels produce carbon emissions along the supply chain.

Advanced biofuels demonstrate high greenhouse gas emission savings.

Biofuels are not sustainable.

Sustainability criteria play an essential role for the market uptake by offering trust and transparency.

Biofuels increase pressure on land use change.

Advanced biofuels indicate a low risk of causing Indirect Land Use Change.

Biofuels are produced from food or trees.

Advanced biofuels by definition are sourced from forest biomass, residues, waste, non-food-crops and do not compete with food or agricultural land-use.

There are better sustainable mobility options than renewable fuels.

Advanced biofuels are amongst the most promising options to reduce carbon emission for aviation and shipping.

THE RESFUEL VALUE CHAIN

The EU Renewable Energy Directive (RED II) sets a target for the contribution of advanced biofuels and biogas of at least 0,2 % in 2022, at least 1 % in 2025 and at least 3,5 % in 2030.

Discover the obstacles and the solutions on the road towards advanced renewable fuels along the value chain!

A well-functioning sustainability framework with effective sustainability criteria and certification is essential to a successful market roll-out of advanced renewable fuels.

Establishing more comprehensive sustainability criteria that include environmental as well as social and economic criteria are crucial to avoid sustainability risks.

- Lack of harmonised regulations

- Clear definitions and guidelines for sustainability requirements

- Develop consistent sustainability criteria & certification applicable for all bio-based end-uses

A well-functioning sustainability framework with effective sustainability criteria and certification is essential to a successful market roll-out of advanced renewable fuels.

Establishing more comprehensive sustainability criteria that include environmental as well as social and economic criteria are crucial to avoid sustainability risks.

- Lack of harmonised regulations

- Clear definitions and guidelines for sustainability requirements

- Develop consistent sustainability criteria & certification applicable for all bio-based end-uses

- Lack of clarity about environmental constraints and land availability

- High cost of feedstock

-

Consider location specific biophysical characteristics which steer environmental constrains

-

The use of marginal land to increase available land for lignocellulosic energy crops production

-

Implementation of innovative cropping schemes could lead to more cost efficient feedstock availability

- Lack of clarity about environmental constraints and land availability

- High cost of feedstock

-

Consider location specific biophysical characteristics which steer environmental constrains

-

The use of marginal land to increase available land for lignocellulosic energy crops production

-

Implementation of innovative cropping schemes could lead to more cost efficient feedstock availability

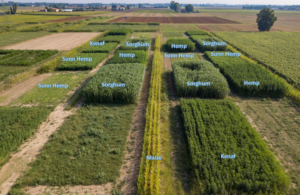

Marginal land

Land of little agricultural value is called marginal land. Land availability and sustainable land use for dedicated biomass production is an essential element to avoid and reduce negative environmental impacts. A spatial explicit approach that assesses the current and future availability of marginal land, and environmental impacts of lignocellulosic energy crops cultivated on these lands will provide some clarity in Europe.

Crop rotation

Crop rotation is another identified innovations to increase yield and, hence, decrease biomass production costs, and at the same time have potentially positive effects on environmental (e.g. erosion, soil fertility, soil organic carbon) and social impacts (e.g. jobs, environmental values).

Source: BECOOL Project

- Absence of policy support and finance

- Concerns on stability of the industry due to financial risks

- Supportive policy framework and instruments

- Symbiosis with current infrastructure

- Further technical learning to reduce production costs requires significant ramp-up of installed capacities

- Absence of policy support and finance

- Concerns on stability of the industry due to financial risks

- Supportive policy framework and instruments

- Symbiosis with current infrastructure

- Further technical learning to reduce production costs requires significant ramp-up of installed capacities

Good practice

Clariant’s constant commitment to innovation and R&D with a strong focus on sustainability has led to the groundbreaking sunliquid® technology to produce cellulosic sugars and ethanol from agricultural residues such as cereal straw, corn stover or sugarcane bagasse. Since 2012, the company is operating its pre-commercial sunliquid® plant in Straubing, Germany and is currently constructing its first-of-its-kind commercial plant in Podari, Southwest Romania. Once operational, the plant will produce 50,000 tons of cellulosic ethanol, processing 250,000 tons of straw per annum. No fossil-based energy sources are required in the sunliquid® process, as it obtains all of its energy from the combustion of residual flows, mainly lignin that remains after extracting the cellulose from the lignocellulose and is, therefore, energy self-sufficient. Taking carbon capture into consideration, the greenhouse gas savings could reach up to ~120%, supporting the transformation from a fossil-based economy to a bio-based circular economy.

Good practice

Clariant’s constant commitment to innovation and R&D with a strong focus on sustainability has led to the groundbreaking sunliquid® technology to produce cellulosic sugars and ethanol from agricultural residues such as cereal straw, corn stover or sugarcane bagasse. Since 2012, the company is operating its pre-commercial sunliquid® plant in Straubing, Germany and is currently constructing its first-of-its-kind commercial plant in Podari, Southwest Romania. Once operational, the plant will produce 50,000 tons of cellulosic ethanol, processing 250,000 tons of straw per annum. No fossil-based energy sources are required in the sunliquid® process, as it obtains all of its energy from the combustion of residual flows, mainly lignin that remains after extracting the cellulose from the lignocellulose and is, therefore, energy self-sufficient. Taking carbon capture into consideration, the greenhouse gas savings could reach up to ~120%, supporting the transformation from a fossil-based economy to a bio-based circular economy.

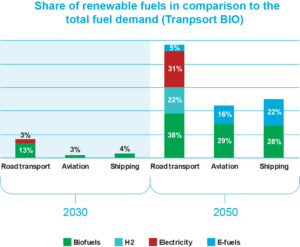

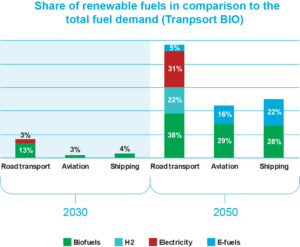

In the ADVANCEFUEL modeling the Transport BIO scenario reflects a significant technology development in the production of advanced biofuels.

In the ADVANCEFUEL modeling the Transport BIO scenario reflects a significant technology development in the production of advanced biofuels.

- Absence of structural mechanism to bridge the price gap between renewable and fossil-based fuels

- High production cost of advanced renewable fuels

- Stable investment climate enabled by policy frameworks, feed-in tariffs, reduction of financial valorisation up to penalisation of fossil fuels

- Reduction of capital and operational expenditures via technical learning and using current infrastructure.

- Absence of structural mechanism to bridge the price gap between renewable and fossil-based fuels

- High production cost of advanced renewable fuels

- Stable investment climate enabled by policy frameworks, feed-in tariffs, reduction of financial valorisation up to penalisation of fossil fuels

- Reduction of capital and operational expenditures via technical learning and using current infrastructure.

Aviation

For aviation, advanced liquid renewables fuels are the only low-carbon option for substituting kerosene, as as they have high energy density and are easier in handling (refueling, storage). They can be used as drop-in Sustainable Sustainable Aviation Fuels (SAFs). Currently, there are five ASTM certified sustainable aviation fuels, utilized commercially and blended up to 50% with fossil jet fuel: Fischer Tropsch fuels, Hydrotreated Esters and Fatty Acids, Renewable Synthesized Iso-Paraffinic, Synthetic paraffinic kerosene with aromatics via Fisher Tropsch and Alcohol-to-jet.

Co-ordinator

Kristin Sternberg

Fachagentur Nachwachsende Rohstoffe (FNR)

k.sternberg@fnr.de

Communications

Simon Hunkin

Greenovate! Europe

s.hunkin@greenovate-europe.eu

Media

Vanessa Wabitsch

REVOLVE

vanessa@revolve.media

![]() This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N.º764799.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N.º764799.